There are many types of cable trays on the market with a wide variety of materials and finishes. When researching, you will encounter products such as powder-coated cable trays, hot-dip galvanized cable trays … So which type is suitable for the requirements of the project? The following is a guide to choosing the right power cable tray, please refer to it.

I. CLASSIFICATION OF CABLE TRAYS BY USED SPACE

1. Cable tray for indoor use

The types of cable trays commonly used for “conventional indoor” construction are powder coated cable trays or galvanized corrugated iron cable trays. “Indoor means sheltered locations from direct sunlight.” These two types of troughs can still be used for “outdoor” environments as long as the cable tray ladders are painted with outdoor powder coating. “Outdoor means locations exposed to direct sunlight and rain.”

However, it is also an indoor environment but there is a volatile solvent, a humid environment or places near the sea, with salt vapor, you should use aluminum or 304 stainless steel troughs. You can also use dipped galvanized cable trays. hot under these conditions. According to VESECO’s assessment, aluminum alloy cable tray is optimal in the above case. It is durable in this environment, but the cost is not as high as 304 stainless steel, so it achieves optimal economic and technical efficiency.

2. Cable tray for outdoor use

For outdoor projects, the hot-dip galvanized cable tray ladder is the most suitable. It achieves the optimum between cost, corrosion resistance and rigidity. Cable tray hot-dip galvanizing is a process of dipping steel cable trays into a bath of molten zinc. Thereby the cable tray is covered with zinc layer to withstand the weather conditions. Examples of weather-resistant hot-dip galvanizing such as bridge railings and street light poles are examples.

II. CLASSIFICATION OF CABLE TRAYS BY STRUCTURE

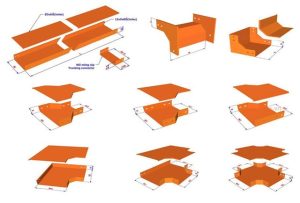

Cable tray systems are classified according to their structure:

- Cable tray with closed bottom

- Cable tray with perforated bottom

- Cable ladder tray

- Grid

- Mesh cable tray

The system also includes the following types:

- Cover: Used to cover the ladder and the connecting details

- Horizontal contraction: Used to redirect the ladder system horizontally

- Numerology or fork: Used to divide the wiring system in three directions

- Cross or crossroads: Used to divide wiring in four directions

- Vertical contraction (up or down): Used to redirect the ladder system vertically.

There are also several types such as:

- Retreat

- Reduced connectors

- Letter Z

- Straight splicing

III. CHOOSE CABLE TRAYS BY CABLES

1. Definitions

- Dimensions in mm

- OD: cable diameter (including insulation, anti-interference)

- OD1…ODn: cable diameter of category 1…n

- ODmax: largest cable diameter

- m1…mn: number of cables of type 1…n

- d: distance between cables

- S: % spare space (for future cabling installation)

- TOD: total diameter of cables

- TW: total installed cable width including distance between cables

- TS: total cross-sectional area of cable installation including redundancy

- F: % installation area 40% 60%

- SC: cross-sectional area of cable tray ladder required for cable installation

- R: radius of contraction, numbness, cross

2. Calculation formula

Calculate the total diameter of the cables TOD = OD1*m1+ … +ODn*mn

Calculate total installed cable width including distance between cables TW = (TOD+d*(m1+…+mn))

Calculate total cross-sectional area of cable installation including redundancy TS = (TW*ODmax)*(1+s/100))

Cable tray cross-sectional area required for cable installation SC = TS*(1+F/100)

Select the cable tray ladder with available height (H) > ODmax from which to calculate the available width (W) > SC/H

Calculate radius of contraction, numbness, cross R = 10*ODmax

3. For example

Calculate the size of cable tray used to install cables with distance between cables d=5mm, spare 20%, mounting area F=50%, quantity and type as follows:

Cadivi CVV Cable 240mm2 → OD=26.6mm. Quantity = 3

Cadivi CVV cable 185mm2 → OD=23.8mm. Quantity = 1

Cadivi CVV cable 95mm2 → OD=17.9mm. Quantity = 3

Cadivi CVV cable 50mm2 → OD=13.9mm. Quantity = 4

Cadivi CVV cable 16mm2 → OD=9.6mm. Quantity = 2

Calculate TOD = 26.6*3+23.8*1+17.9*3+13.9*4+9.6*2 = 232.1

Calculate TW = 232.1+5*(3+1+3+4+2) = 297.1

Calculate TS = 297.1*26.6*(1+20/100) = 9483

Calculate SC = 9483*(1+50/100) = 14225

With cable tray with H = 50 → W = 14225/50 = 284.5 → Select cable tray H = 50mm, W = 300mm

With cable tray with H = 100 → W = 14225/100 = 142.25 → Select cable tray H = 100mm, W = 150mm

Calculate R = 10*26.6 = 266 → Choose radius of contraction, numbness, cross R = 300mm.

The above are guidelines for choosing the right cable tray for each type of project. Invite your reference. For more necessary information about our products, please contact Hotline: (+84) 904 571 488. Best Regards./.