For each wastewater treatment plant, it is essential to install an electrical control panel for wastewater treatment. So how important is the wastewater treatment control cabinet for the wastewater treatment operation of the plant, with the development of the current electrical cabinet, it is impossible not to mention the wastewater treatment cabinet. Wastewater treatment electrical cabinet is an electrical cabinet that controls the wastewater treatment process by controlling the pump, agitator, metering pump, air blower, electric valve, etc. through switchgear in electrical cabinets. To meet the output targets of wastewater. Let’s find out with VESA about “Details of electrical cabinets to control wastewater treatment stations”.

Function of the control cabinet of the wastewater treatment plant

– It is considered as the brain of the entire system, making it easier, more accurate and convenient to control devices. The electrical cabinet controls and coordinates the operation of all equipment in the system.

– Protective electrical cabinets combined with measuring actuators such as: Level measuring device, DO meter, PH meter, blower, pump… to ensure normal and continuous operation of the system.

– Continuously and accurately update the operating status of the equipment, the system status with the operator through indicator lights, HMI screen, SCADA computer.

– Meet the requirements of electrical safety, simplify the operation process.

Classification of electrical cabinets controlling wastewater treatment plants

Based on the operation features, the control cabinet of the wastewater treatment station can be divided into 3 main types:

– Manual control cabinet: For electrical cabinets of this type, the operator directly manipulates manually by switches or buttons so that the system operates according to the operating principle to meet the standard output water quality. This mode requires an experienced operator and closely monitors the electrical cabinet. Currently, this electrical cabinet is almost not used for the electrical system of wastewater treatment cabinets.

– Semi-automatic control cabinet: For this type of electrical cabinet, most of the equipment will run automatically according to the float and time relay. In addition, there will be a number of hand-operated pumps such as chemical pumps, stirrers, etc. This type of electrical cabinet is quite commonly used today with wastewater treatment stations under 500 m³ because of its reasonable price and meeting waste water treatment requirements.

– Automatic control cabinet: This type of electrical cabinet is commonly used in wastewater treatment stations over 500 m³. This electrical cabinet will operate on the principle of collecting the signals of the leveling float, the oxygen concentration sensor (DO sensor), the PH concentration sensor, the flow meter to the central controller PLC; combined with set values of time, concentration, alternate mode, etc. on PC or HMI control screen to control wastewater treatment system according to programmed program based on technology requirements ; meet the requirements of accurate operation and save on chemical costs, save electricity costs through the use of acid/caustic soda metering pumps running according to the set pH threshold, using inverters for motors of air blower.

Details of electrical cabinets to control wastewater treatment station

The basic structure of the control cabinet includes the following three main components:

– Switchgear

– Device Drivers

– Other auxiliary equipment

1. Switchgear

Switchgear includes a variety of devices such as (Aptomat, magnetic starter, thermal role, fuse, etc.) with the function of switching and disconnecting the current in normal and abnormal conditions.

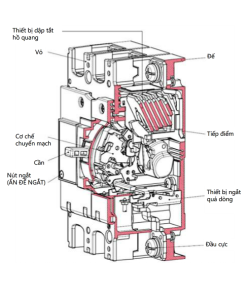

Aptomat

Aptomat is an electrical device that everyone must have heard of. Basically, Aptomat is a type of circuit breaker with the ability to automatically switch. In an electrical system, Aptomat has the function of protecting the system from overload or short circuit. Some models also have advanced functions such as anti-leakage or anti-shock.

Some of the most important Aptomat benefits can be listed as follows:

- Automatically disconnect current in electrical systems when a short circuit or voltage drop occurs.

- Protect electrical equipment from damage when the power system encounters unexpected problems.

- When current is leaked to ground, an imbalance between outgoing and returning currents will occur. Aptomat will be used to disconnect power in this case.

- If an electric shock occurs, Aptomat also automatically cuts off the power to protect people.

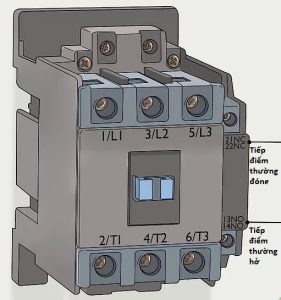

Start from

Magnetic starter , also known as contactor or contactor in Vietnamese words, is a particularly important low-voltage electrical instrument in electrical systems. It is responsible for the regular closing and breaking of the dynamic electrical circuits.

Some features of word boot:

- To ensure the safety of users when there is a remote switch-off mode, and in malicious systems, there is a cover to prevent arcing.

- Stable, durable, trouble-free operation. Suitable for use in complex, large-capacity electrical equipment and systems.

- Compact design with quite light weight and sturdy, can be installed in many different locations and take advantage of tight spaces.

- Reasonably priced, easy to find in the market.

- Quick power on and off time, effectively saving power consumption.

- The main contacts, auxiliary contacts of the contactor can withstand high corrosion, good wear resistance.

Heat Role

Thermal relay (also known as Thermal Relay, Thermal Relay) is a type of electrical device used to protect motors and electrical circuits from overload, often used in conjunction with Contractors. The thermal relay has the function of automatically switching the contacts due to the thermal expansion of the metal rods.

Thermal relay is installed with Contactor (magnetic starter) to protect electrical equipment, especially electric motor, when overcurrent, overload during operation. Note: The thermal relay only changes the contact state, but does not automatically disconnect the power supply, so it must be combined with another switching device.

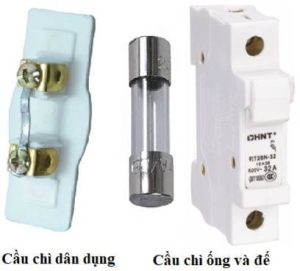

Fuse

Fuse (Fuse) is an electrical instrument used to protect equipment and the power grid from short-circuits, limiting fire and explosion. More specifically, a fuse is a device used to protect conductors, electrical equipment and circuits under overloaded circuit or current conditions. They are connected directly between electrical conductors and electrical devices. This tool has a simple structure, small size, low price, so it is widely used in electrical systems.

2. Device Drivers

As the name suggests, control devices have the function of controlling the operation of devices in the system. Can simply control On/Off in real time with Timer, or according to the leveling signal with Intermediate Role or flexible and complex control with PLC.

Timer Controller

Timer is a switching device with opening or closing contacts that can automate the control of devices in the power system, they can also adjust the time delay of the RTG. Thanks to those functions, the timer is also known by many other names such as: time relay, on-off timer switch, clock switch, etc.

Currently, timers are divided into 3 main types as follows:

- Mechanical Timer: A set of manual switches, manually adjusted on and off.

- Electronic Timer: Has higher accuracy, has a timer system at will.

- Timer 24h: is a line of timers with a cycle of 24 hours.

PLC controller

PLC stands for Programmable Logical Controller, which means programmed automatic control program. This program is stored in ROM memory and loaded into the PLC through a personal computer. In each PLC, a program determines the function the controller needs to perform, which is then loaded into the PLC. PLC memory. At that time, the PLC will perform the control process based on the pre-loaded program.

Compared with Timer, PLC programmer has many outstanding features such as:

- Program data storage and processing: The PLC connects inputs and outputs to the rest of the machine. Meanwhile, the I/O modules provide information so that the CPU can activate and display specific results. Thus, I/O can be digital with input devices including: switches, sensors, and output clocks. But output devices will include: drives, relays, valves and lights. During installation, the user can choose how to combine the PLC’s I/O to create a configuration that is suitable for the actual application.

- Communication: PLC also has the ability to combine with other systems to perform communication tasks.

- HMI: To be able to interact with PLC in real time, HMI is a necessary choice. These can be simple screens or text reading screens or more modern can be touch screen panels. Regardless of which screen is used, the purpose of this combination is to help users view and enter information into the PLC most accurately.

3. Other auxiliary equipment

Electrical enclosure

Electrical cabinets are products used to contain equipment such as: Aptomat, circuit breakers, power meters, transformers, transformers, controllers, etc. They are often used in factories, production workshops, etc. civil electricity construction projects. They are designed and manufactured according to the product’s own industry standards.

The normal electrical cabinet cover will be rectangular, square, with 1 or 2 layers of wings, the front side is fitted with a power indicator meter, signal lights, control panel, display screen, etc. depends on the design requirements from the user unit.

Intermediate role

Intermediate relays are very small electronic devices that have the function of switching control signals and amplifying them. They are used a lot in the circuit boards. In the control scheme, the intermediate relay is always placed in the contact position between the control devices with small capacity and large capacity equipment.

There are many types of intermediate relays. Currently, they are classified as follows:

- According to electrical capacity, including: Intermediate role 5V, 12V, 24VDC.

- According to the pin structure: Intermediate role 5 pins, 8 pins and 14 pins.

Lights

phase lights are an extremely important and indispensable device in the electrical panel system in industry. This device has the main task of indicating phase, helping users easily identify the operating status of the system.

Some of the benefits of warning lights include:

- Can display ON – OFF status of machines and equipment. Typically, electrical engineers will install a green light to indicate when the machine is working, and a red light to indicate when the device has stopped working.

- Able to detect errors quickly, warn users about problems in operating machinery to promptly handle and avoid damage to people and property.

- Capable of displaying a power notification when using 3-phase or 1-phase power.

Rotating

Rotary switch is a device with a special structure, which helps to switch the operating state of the device. The 3-position rotary switch is composed of: a spring-loaded system, a system of normally open (NO) – normally closed (NC) contacts and a protective cover. When turning the rotary switch 45 degrees (3 positions) or 90 degrees (2 positions), the contacts change state. When no longer active, the contacts return to their original state or keep themselves depending on the needs and design of the rotary switch.

Button

Switchboard push button is a kind of tool used to turn on / off electrical equipment, machinery or some kind of process in control.

There are many ways to classify pushbuttons. Below, VESECO lists some common types of push buttons:

- Push button without light: Used to control signals of industrial or civil electrical panel systems.

- Push button with light: Used to control signals of industrial or civil electrical panel systems. Capable of helping to receive signals remotely through the light built into the push button.

- Emergency stop button: A push button used to stop the machine in emergency cases. Thanks to the design of the large button head so that in case of an emergency, it can be operated easily. When affected, the emergency stop button maintains the state, to return to the original operation, the push button must be rotated.

Voltage and current measuring equipment

Use to measure voltage (Voltmeter), amperage (Ammeter) or many different parameters (Multimeter) . Helps detect system power or operation abnormalities. May be accompanied by some auxiliary equipment such as current transformers (CT) or switches.

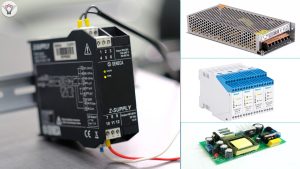

Power adapter

The power converter is used to convert power from AC voltage 380/220VAC to a lower voltage or to DC current for use in control circuits, powering sensors, small devices…

Thus, through this article, VESA has summarized the functions and detailed structure of the control cabinet in a wastewater treatment system. Due to playing a very important role, electrical cabinets need to achieve quality, safety, ease of operation and high accuracy. VESA with many years of experience in designing and installing industrial electrical cabinets in general and electrical cabinets for wastewater treatment systems in particular. With large and small projects of long-term partners such as: Daewoo, Tasaco, Sun Group… We are confident to bring customers solutions that meet technical requirements and optimize costs.

Please contact us immediately via Hotline (+84) 904 571 488 for direct advice.