1. Overview of asynchronous motors

1.1. What are asynchronous motors?

– Is the main engine in industry

– Simple structure, low cost

– Easy operation

– Working reliably

Structure of asynchronous motor

1.2 Basic requirements start an engine:

When starting an engine we need to consider the following basic requirements:

– The starting torque must be large enough to accommodate the mechanical properties of the load.

– The smaller the starting current, the better

– The method of starting and the equipment to be used is simple, cheap, and reliable.

– The power loss in the process of leaving the engine as low as possible.

2. Engine starting methods

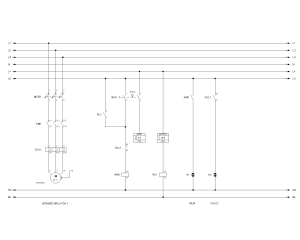

2.1 Direct engine start:

As the simplest starting method, simply plug the electric motor into the grid with the appropriate voltage:

– Starting voltage = 100%

– Starting current = (4 to 8).In

– Starting torque = (0.6 to 1.5).Tn

Advantages :

– Quick start up.

– Simple starting device > low cost

– Large starting torque

Defect :

– Large motor starting current

– If the inertia of the load is large, the starting time is prolonged > causing a voltage drop on the grid, making the engine hot.

– Shock and mechanical wear when starting

Application :

– The transmission machines, machine tools with small capacity, usually start with load.

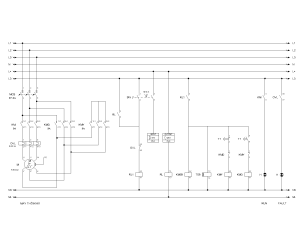

2.2 Start the engine Y/D

Suitable for engines when working normally in delta connection. When opening the machine, wechange it to Y, so the voltage applied to the two ends of each phase is reduced by 3 times.

– Starting voltage = 58%

– Starting current = (1.3 to 2.6).In

– Starting torque = (0.6 to 1.5).Tn

Advantages :

– Simple starter kit, cheap

– Low starting current limitation

Defect :

– Low starting torque

– Engine parameters cannot be adjusted when starting.

– Y/D conversion leads to large current transients

Application :

– Applicable to engines when working in triangle connection.

– Engine idling or small load (centrifugal pump, fan…)

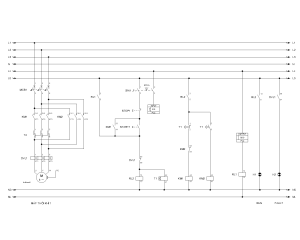

2.3 Starting the motor with an autotransformer

– Starting voltage = 40/65/80 %

– Starting current = (1.7 to 4).In

– Starting torque = (0.4 to 0.85).Tn

Advantages :

– Suitable starting torque/current characteristic

– Start-up parameters can be adjusted

– No interruption of power supply when switching

Defect :

– Large autotransformer cost.

– Limit the number of starts.

Application :

– The motor has a large moment of inertia, when starting, it is required to limit the starting current.

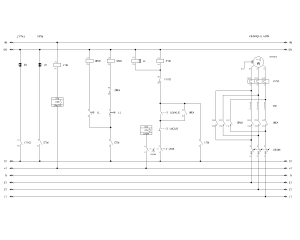

2.4 Starting the motor with the auxiliary reactor

– Starting current is 1.7 to 4 times more than rated current

– Starting torque is less than 0.5 to 0.85 times of rated torque

Advantages :

– Contacts have high wear resistance.

– High closing – cutting capacity.

– Action close – cut definitively.

– Consume less power

– Protect the motor from long-term overload (with thermal relay).

Defect :

– The starting voltage cannot be adjusted.

Application :

– The motor has a large moment of inertia

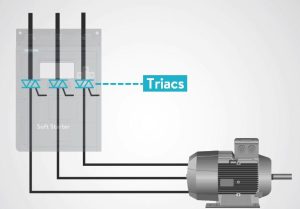

2.5 Start the engine with a soft starter

The soft starter device uses thyristors to control the voltage supplied to the motor, thereby reducing the starting current and making the motor acceleration not increase suddenly and at the same time limit the voltage drop of the transformer when starting. starter motor.

Advantages :

– Limited inrush current

– Precise torque adjustment

– Limit mechanical wear

Defect :

– Cannot adjust working frequency

– High price

Application :

– Used for most types of engines

2.6 Starting the motor with an inverter

The most comprehensive startup method. Not only limiting the starting current, integrated with many safety features, motor protection modes such as phase loss, phase difference, overvoltage, overheating, overload, low voltage … smooth starting mode, helping to protect Protects machine components such as gearboxes, bearings, drums, and modern technologies such as PID controller, start-up mode, pipeline cleaning mode, load torque monitoring, comprehensive dynamic protection three-phase asynchronous motor.

Advantages :

– Limited inrush current

– Precise torque adjustment

– Limit mechanical wear

– Change the motor speed flexibly, reverse the motor

– Flexible adjustment of acceleration and deceleration time.

– Multiple engine and mechanical system protection functions

Defect :

– High price

Application :

– Used for most types of engines

Above is the information we share to answer about the methods of starting the engine and choosing the right equipment. Hopefully, this knowledge will help you to understand the knowledge of the engine and find the best solution for your project.

Please contact VESECO for advice and purchase genuine products at the most reasonable price.